VEHICLE SPEED SENSOR (VSS) INSPECTION

BHE051319200W08

-

Caution

-

• Water or foreign material entering the connector can cause poor connections or corrosion. Be sure that water or foreign material do not enter the connector when disconnecting it.

Visual Inspection

1. Remove the VSS. (See VEHICLE SPEED SENSOR (VSS) REMOVAL/INSTALLATION.)

2. Make sure that the VSS is free of any metal shavings or particles.

-

• If there is any malfunction, clean them off.

3. Install the VSS. (See VEHICLE SPEED SENSOR (VSS) REMOVAL/INSTALLATION.)

Element inspection

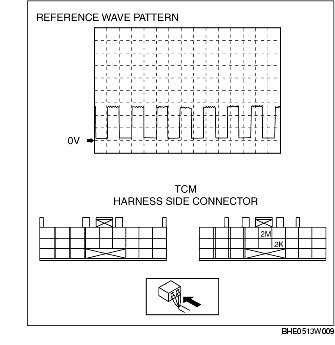

1. Verify using an oscilloscope that the wave pattern for the VSS signal that is input to TCM terminal 2K is the same as the reference wave pattern.

-

• If the actual pattern of the VSS signal is not the same as the reference pattern, inspect and repair the following items:

|

Wave pattern

|

Malfunction cause

|

|

No wave pattern (fixed at HI)

|

• Open circuit between VSS terminal (A)-TCM terminal 2K

• Open/Short circuit between VSS terminal (B)-battery

|

|

No wave pattern (fixed at LO)

|

• Short circuit between VSS terminal (A)-TCM terminal 2K

|

|

Wave pattern HI is too low

|

• Harness malfunction between VSS terminal (A)-TCM terminal 2K

• Insufficient output from the VSS

|

|

Wave pattern LO is too high

|

• Poor connection (loose GND) between VSS terminal (C)-TCM terminal 2K

|

|

Wave pattern too wide/narrow

|

• Metal shavings (foreign material) on VSS

• Parking gear rotation fluctuation

|

-

• Connected terminals: 2K (+) and 2M (-)

-

• Equipment setting: 5V/DIV (Y): 2.5 ms/DIV (X)

-

• Measuring conditions: M range, 1st gear at 20 km/h {12 mph}

2. Verify the wave pattern of the VSS signal again, and if the malfunction is not resolved, replace the VSS.